Engineered Castable Polyurethane Elastomers for Superior Performance and Durability

Polycoat Products’ hot and cold cast elastomers deliver unmatched strength, abrasion resistance and versatility across industries from mining and oil and gas to electronics, transportation and recreation.

Using advanced chemistries and precision processing, our systems create molded components that outperform metal and rubber, extend equipment life and withstand the most demanding environments. Backed by in-house testing and engineering support, we help customers achieve the exact balance of performance, longevity and cost efficiency their applications require.

Applications

- Mining and Aggregate Processing

- Oil and Gas Industry Solutions

- Industrial and Recreational Wheels

- Electronics, Manufacturing and Specialty Uses

Mining and Aggregate Processing

Polycoat castable elastomers withstand extreme abrasion and impact, extending the life of equipment used in mining, concrete and aggregate operations. Designed for strength and durability, they outperform metal liners and reduce costly downtime.

Common Applications

- Chute and hopper liners

- Urethane mining screens

- Conveyor and handling components

Oil and Gas Industry Solutions

From pipelines to drilling equipment, our castable polyurethane elastomers deliver superior wear resistance and performance in harsh oilfield environments. They clean, protect and extend the service life of critical infrastructure.

Common Applications

- Pipeline pigs and smart pigs

- Drilling and frac equipment parts

- Product separation seals

Industrial and Recreational Wheels

Polycoat elastomers provide high load-bearing capacity, resilience and abrasion resistance for wheels used in industrial and recreational applications. With precision engineering, they perform under pressure while ensuring long-term reliability.

Common Applications

- Forklift and warehouse tires

- Roller coaster and amusement wheels

- Skateboard and inline skate wheels

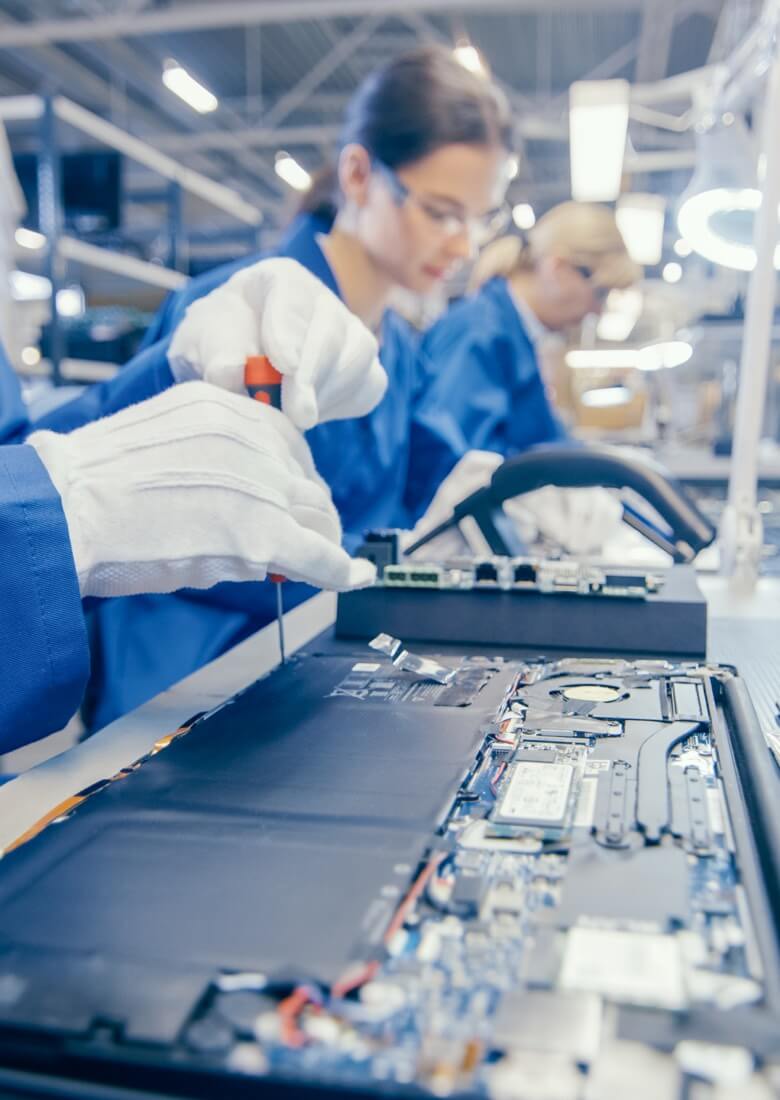

Electronics, Manufacturing and Specialty Uses

Our urethane systems enable high-precision parts and specialty products across industries such as electronics, pulp and paper and recreation. Engineered for demanding conditions, they help produce consistent results in critical processes.

Common Applications

- CMP and specialty polishing pads

- Urethane-covered industrial rolls

- Golf balls and specialty recreation products

Resources

Watch Videos, Download Specs, Guides and More

Access technical data sheets, performance testing results and application guides to see how Polycoat castable elastomers are engineered and applied across industries.

Collaborative Development for Performance and Reliability

Polycoat Products collaborates with customers to develop hot and cold cast elastomer systems that meet exact performance, processing and cost requirements. From lab-scale testing to full-scale production, our chemists and engineers provide solutions tailored to each application.

- Test pours with customer molds for real-world validation

- Formulations optimized for abrasion, chemical or water resistance

- Engineering support with FEA modeling and performance testing

Contact Us

Ready to Get Started?

Connect with our team to discuss your next project and discover the right Polycoat solution for your needs.