Page 112 - Polycoat 1.1 Table of Contents

P. 112

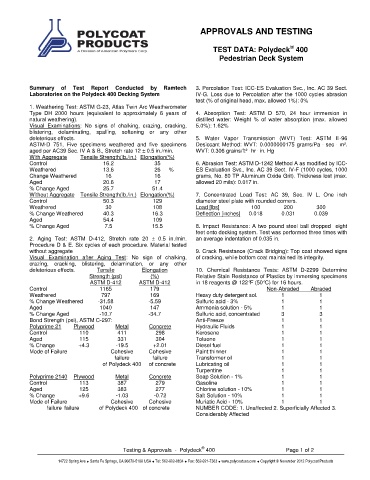

1 APPROVALS AND TESTING

®

TEST DATA: Polydeck 400

Pedestrian Deck System

Summary of Test Report Conducted by Ramtech 3. Percolation Test: ICC-ES Evaluation Svc., Inc. AC 39 Sect.

Laboratories on the Polydeck 400 Decking System IV-G. Loss due to Percolation after the 1000 cycles abrasion

test (% of original head, max. allowed 1%): 0%

1. Weathering Test: ASTM G-23, Atlas Twin Arc Weatherometer

Type DH 2000 hours (equivalent to approximately 6 years of 4. Absorption Test: ASTM D 570, 24 hour immersion in

natural weathering). distilled water: Weight % of water absorption (max. allowed

Visual Examinations: No signs of chalking, crazing, cracking, 5.0%): 1.62%

blistering, delaminating, spalling, softening or any other

deleterious effects. 5. Water Vapor Transmission (WVT) Test: ASTM E-96

ASTM-D 751, Five specimens weathered and five specimens Desiccant Method: WVT: 0.0000000175 grams/Pa sec m².

.

.

aged per AC39 Sec. IV A & B., Stretch rate 12 ± 0.5 in./min. WVT: 0.306 grains/ft² hr in. Hg

.

.

With Aggregate Tensile Strength(lb./in.) Elongation(%)

Control 16.2 35 6. Abrasion Test: ASTM D-1242 Method A as modified by ICC-

Weathered 13.6 26 % ES Evaluation Svc., Inc. AC 39 Sect. IV-F (1000 cycles, 1000

Change Weathered 16 16 grams, No. 80 TP Aluminum Oxide Grit). Thickness lost (max.

Aged 20.6 17 allowed 20 mils): 0.017 in.

% Change Aged 25.7 51.4

Without Aggregate Tensile Strength(lb./in.) Elongation(%) 7. Concentrated Load Test: AC 39, Sec. IV L. One inch

Control 50.3 129 diameter steel plate with rounded corners.

Weathered 30 108 Load [lbs] 100 200 300

% Change Weathered 40.3 16.3 Deflection [inches] 0.018 0.031 0.039

Aged 54.4 109

% Change Aged 7.5 15.5 8. Impact Resistance: A two pound steel ball dropped eight

feet onto decking system. Test was performed three times with

2. Aging Test: ASTM D-412, Stretch rate 20 ± 0.5 in./min. an average indentation of 0.035 in.

Procedure D & E. Six cycles of each procedure. Material tested

without aggregate 9. Crack Resistance (Crack Bridging): Top coat showed signs

Visual Examination after Aging Test: No sign of chalking, of cracking, while bottom coat maintained its integrity.

crazing, cracking, blistering, delamination, or any other

deleterious effects. Tensile Elongation 10. Chemical Resistance Tests: ASTM D-2299 Determine

Strength (psi) (%) Relative Stain Resistance of Plastics by immersing specimens

ASTM D-412 ASTM D-412 in 18 reagents @ 122°F (50°C) for 16 hours.

Control 1165 179 Non-Abraded Abraded

Weathered 797 169 Heavy duty detergent sol. 1 1

% Change Weathered -31.58 -5.59 Sulfuric acid - 3% 1 1

Aged 1040 147 Ammonia solution - 5% 1 1

% Change Aged -10.7 -34.7 Sulfuric acid, concentrated 3 3

Bond Strength (psi), ASTM C-297: Anti-Freeze 1 1

Polyprime 2 1 Plywood Metal Concrete Hydraulic Fluids 1 1

Control 110 411 298 Kerosene 1 1

Aged 115 331 304 Toluene 1 1

% Change +4.3 -19.5 +2.01 Diesel fuel 1 1

Mode of Failure Cohesive Cohesive Paint thinner 1 1

failure failure Transformer oil 1 1

of Polydeck 400 of concrete Lubricating oil 1 1

Turpentine 1 1

Polyprime 2140 Plywood Metal Concrete Soap Solution - 1% 1 1

Control 113 387 279 Gasoline 1 1

Aged 125 383 277 Chlorine solution - 10% 1 1

% Change +9.6 -1.03 -0.72 Salt Solution - 10% 1 1

Mode of Failure Cohesive Cohesive Muriatic Acid - 10% 1 1

failure failure of Polydeck 400 of concrete NUMBER CODE: 1. Unaffected 2. Superficially Affected 3.

Considerably Affected

®

Testing & Approvals - Polydeck 400 Page 1 of 2

14722 Spring Ave Santa Fe Springs, CA 90670-5108 USA Tel: 562-802-8834 Fax: 562-921-7363 www.polycoatusa.com Copyright ® November 2012 Polycoat Products