Page 283 - Polycoat 1.1 Table of Contents

P. 283

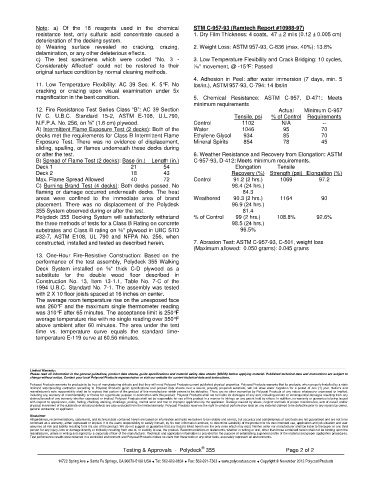

Note: a) Of the 18 reagents used in the chemical STM C-957-93 (Ramtech Report #10988-97)

resistance test, only sulfuric acid concentrate caused a 1. Dry Film Thickness: 4 coats, 47 ± 2 mils (0.12 ± 0.005 cm)

deterioration of the decking system.

b) Wearing surface revealed no cracking, crazing, 2. Weight Loss: ASTM 957-93, C-836 (max. 40%): 13.8%

delamination, or any other deleterious effects.

c) The test specimens which were coded “No. 3 - 3. Low Temperature Flexibility and Crack Bridging: 10 cycles,

Considerably Affected” could not be restored to their d" movement, @ -15°F: Passed

original surface condition by normal cleaning methods.

4. Adhesion in Peel: after water immersion (7 days, min. 5

11. Low Temperature Flexibility: AC 39 Sec. K. 5°F. No lbs/in.), ASTM 957-93, C-794: 14 lbs/in

cracking or crazing upon visual examination under 5x

magnification in the bent condition. 5. Chemical Resistance: ASTM C-957, D-471: Meets

minimum requirements

12. Fire Resistance Test Series Class “B”: AC 39 Section

Actual Minimum C-957

IV C. U.B.C. Standard 15-2, ASTM E-108, U.L.790, Tensile, psi % of Control Requirements

N.F.P.A. No. 256, on b" (1.6 cm) plywood. Control 1102 N/A --

A) Intermittent Flame Exposure Test (2 decks): Both of the Water 1046 95 70

decks met the requirements for Class B Intermittent Flame Ethylene Glycol 934 85 70

Exposure Test. There was no evidence of displacement, Mineral Spirits 854 78 45

sliding, spalling, or flames underneath these decks during

or after the test. 6. Weather Resistance and Recovery from Elongation: ASTM

B) Spread of Flame Test (2 decks): Base (in.) Length (in.) C-957-93, D-412: Meets minimum requirements.

Deck 1 21 54 Elongation Tensile

Deck 2 18 43 Recovery (%) Strength (psi) Elongation (%)

Max. Flame Spread Allowed 40 72 Control 91.2 (2 hrs.) 1069 97.2

C) Burning Brand Test (4 decks): Both decks passed. No 98.4 (24 hrs.)

flaming or damage occurred underneath decks. The heat 84.3

areas were confined to the immediate area of brand Weathered 90.3 (2 hrs.) 1164 90

placement. There was no displacement of the Polydeck 96.9 (24 hrs.)

355 System observed during or after the test. 81.4

Polydeck 355 Decking System will satisfactorily withstand % of Control 99 (2 hrs.) 108.8% 92.6%

the three methods of tests for a Class B Rating on concrete 98.5 (24 hrs.)

substrates and Class B rating on b" plywood in UBC STD 96.5%

#32-7, ASTM E108, UL 790 and NFPA No. 256, when

constructed, installed and tested as described herein. 7. Abrasion Test: ASTM C-957-93, C-501, weight loss

(Maximum allowed: 0.050 grams): 0.045 grams

13. One-Hour Fire-Resistive Construction: Based on the

performance of the test assembly, Polydeck 355 Walking

Deck System installed on b" thick C-D plywood as a

substitute for the double wood floor described in

Construction No. 13, Item 13-1.1, Table No. 7-C of the

1994 U.B.C. Standard No. 7-1. The assembly was tested

with 2 X 10 floor joists spaced at 16 inches on center.

The average room temperature rise on the unexposed face

was 260°F and the maximum single thermometer reading

was 310°F after 65 minutes. The acceptance limit is 250°F

average temperature rise with no single reading over 350°F

above ambient after 60 minutes. The area under the test

time vs. temperature curve equals the standard time-

temperature E-119 curve at 60.56 minutes.

______________________________________________________________________________________________________________________________________

Limited Warranty:

Please read all information in the general guidelines, product data sheets, guide specifications and material safety data sheets (MSDS) before applying material. Published technical data and instructions are subject to

change without notice. Contact your local Polycoat Products representative or visit our website for current technical data and instructions.

Polycoat Products warrants its products to be free of manufacturing defects and that they will meet Polycoat Products current published physical properties. Polycoat Products warrants that its products, when properly installed by a state

licensed waterproofing contractor according to Polycoat Products guide specifications and product data sheets over a sound, properly prepared substrate, will not allow water migration for a period of one (1) year. Seller’s and

manufacturer’s sole responsibility shall be to replace that portion of the product of this manufacturer which proves to be defective. There are no other warranties by Polycoat Products of any nature whatsoever expressed or implied,

including any warranty of merchantability or fitness for a particular purpose in connection with this product. Polycoat Products shall not be liable for damages of any sort, including remote or consequential damages resulting from any

claimed breach of any warranty whether expressed or implied. Polycoat Products shall not be responsible for use of this product in a manner to infringe on any patent held by others. In addition, no warranty or guarantee is being issued

with respect to appearance, color, fading, chalking, staining, shrinkage, peeling, normal wear and tear or improper application by the applicator. Damage caused by abuse, neglect and lack of proper maintenance, acts of nature and/or

physical movement of the substrate or structural defects are also excluded from the limited warranty. Polycoat Products reserves the right to conduct performance tests on any material claimed to be defective prior to any repairs by owner,

general contractor, or applicator.

Disclaimer:

All guidelines, recommendations, statements, and technical data contained herein are based on information and tests we believe to be reliable and correct, but accuracy and completeness of said tests are not guaranteed and are not to be

construed as a warranty, either expressed or implied. It is the users responsibility to satisfy himself, by his own information and test, to determine suitability of the product for his own intended use, application and job situation and user

assumes all risk and liability resulting from his use of the product. We do not suggest or guarantee that any hazard listed herein are the only ones which may exist. Neither seller nor manufacturer shall be liable to the buyer or any third

person for any injury, loss or damage directly or indirectly resulting from use of, or inability to use, the product. Recommendations or statements, whether in writing or oral, other than those contained herein shall not be binding upon the

manufacturer, unless in writing and signed by a corporate officer of the manufacturer. Technical and application information is provided for the purpose of establishing a general profile of the material and proper application procedures.

Test performance results were obtained in a controlled environment and Polycoat Products makes no claim that these tests or any other tests, accurately represent all environments.

®

Testing & Approvals - Polydeck 355 Page 2 of 2

14722 Spring Ave Santa Fe Springs, CA 90670-5108 USA Tel: 562-802-8834 Fax: 562-921-7363 www.polycoatusa.com Copyright ® November 2012 Polycoat Products