Page 112 - tmp

P. 112

TECHNICAL DATA SHEET | Section 6.1

PC-220 / 220SC

Elastomeric, Aromatic-Polyurethane Base Membrane

Product Description

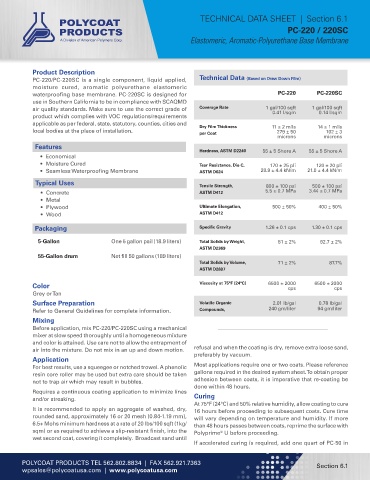

PC-220/PC-220SC is a single component, liquid applied, Technical Data (Based on Draw Down Film)

moisture cured, aromatic polyurethane elastomeric

waterproofing base membrane. PC-220SC is designed for PC-220 PC-220SC

use in Southern California to be in compliance with SCAQMD

air quality standards. Make sure to use the correct grade of Coverage Rate 1 gal/100 sqft 1 gal/100 sqft

product which complies with VOC regulations/requirements 0.41 l/sqm 0.14 l/sqm

applicable as per federal, state, statutory, counties, cities and Dry Film Thickness 11 ± 2 mils 14 ± 1 mils

local bodies at the place of installation. per Coat 279 ± 50 102 ± 3

microns microns

Features

Hardness, ASTM D2240 55 ± 5 Shore A 55 ± 5 Shore A

• Economical

• Moisture Cured Tear Resistance, Die C, 170 ± 25 pli 120 ± 20 pli

• Seamless Waterproofing Membrane ASTM D624 28.9 ± 4.4 kN/m 21.0 ± 4.4 kN/m

Typical Uses Tensile Strength, 800 ± 100 psi 500 ± 100 psi

• Concrete ASTM D412 5.5 ± 0.7 MPa 3.44 ± 0.7 MPa

• Metal

• Plywood Ultimate Elongation, 500 ± 50% 400 ± 50%

• Wood ASTM D412

Packaging Specific Gravity 1.26 ± 0.1 cps 1.30 ± 0.1 cps

5-Gallon One 5 gallon pail (18.9 liters) Total Solids by Weight, 81 ± 2% 92.7 ± 2%

ASTM D2369

55-Gallon drum Net fill 50 gallons (189 liters)

Total Solids by Volume, 71 ± 2% 87.7%

ASTM D2697

Color Viscosity at 75°F (24°C) 6500 ± 2000 6500 ± 2000

cps

cps

Grey or Tan

Surface Preparation Volatile Organic 2.01 lb/gal 0.78 lb/gal

Refer to General Guidelines for complete information. Compounds, 240 gm/liter 94 gm/liter

Mixing

Before application, mix PC-220/PC-220SC using a mechanical

mixer at slow speed thoroughly until a homogeneous mixture

and color is attained. Use care not to allow the entrapment of

air into the mixture. Do not mix in an up and down motion. refusal and when the coating is dry, remove extra loose sand,

preferably by vacuum.

Application

For best results, use a squeegee or notched trowel. A phenolic Most applications require one or two coats. Please reference

resin core roller may be used but extra care should be taken gallons required in the desired system sheet. To obtain proper

not to trap air which may result in bubbles. adhesion between coats, it is imperative that re-coating be

done within 48 hours.

Requires a continuous coating application to minimize lines

and/or streaking. Curing

At 75°F (24°C) and 50% relative humidity, allow coating to cure

It is recommended to apply an aggregate of washed, dry, 16 hours before proceeding to subsequent coats. Cure time

rounded sand, approximately 16 or 20 mesh (0.84-1.19 mm), will vary depending on temperature and humidity. If more

6.5+ Mohs minimum hardness at a rate of 20 lbs/100 sqft (1kg/ than 48 hours passes between coats, reprime the surface with

sqm) or as required to achieve a slip-resistant finish, into the Polyprime U before proceeding.

®

wet second coat, covering it completely. Broadcast sand until

If accelerated curing is required, add one quart of PC-50 in

POLYCOAT PRODUCTS TEL 562.802.8834 | FAX 562.921.7363 Section 6.1

wpsales@polycoatusa.com | www.polycoatusa.com